Design for Manufacturing and Assembly (DfMA)

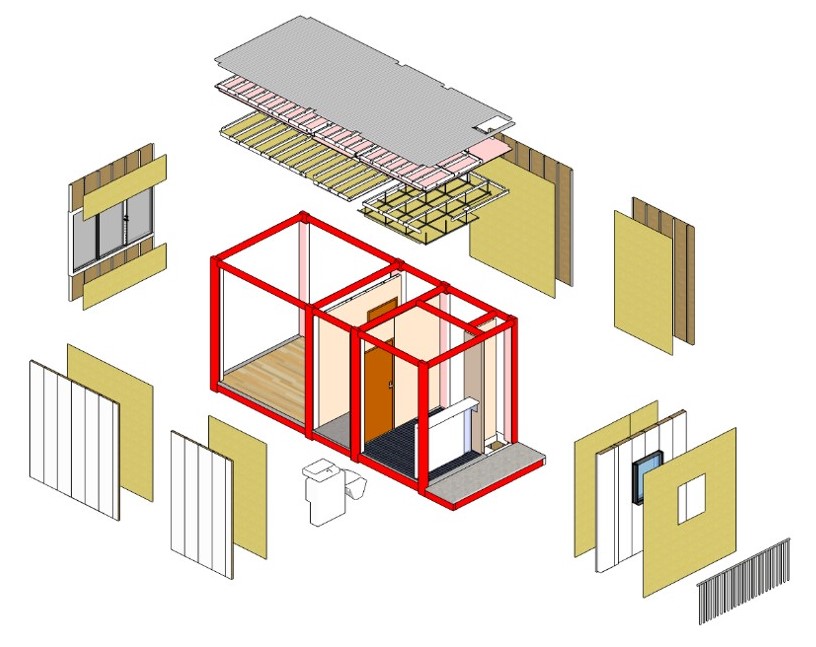

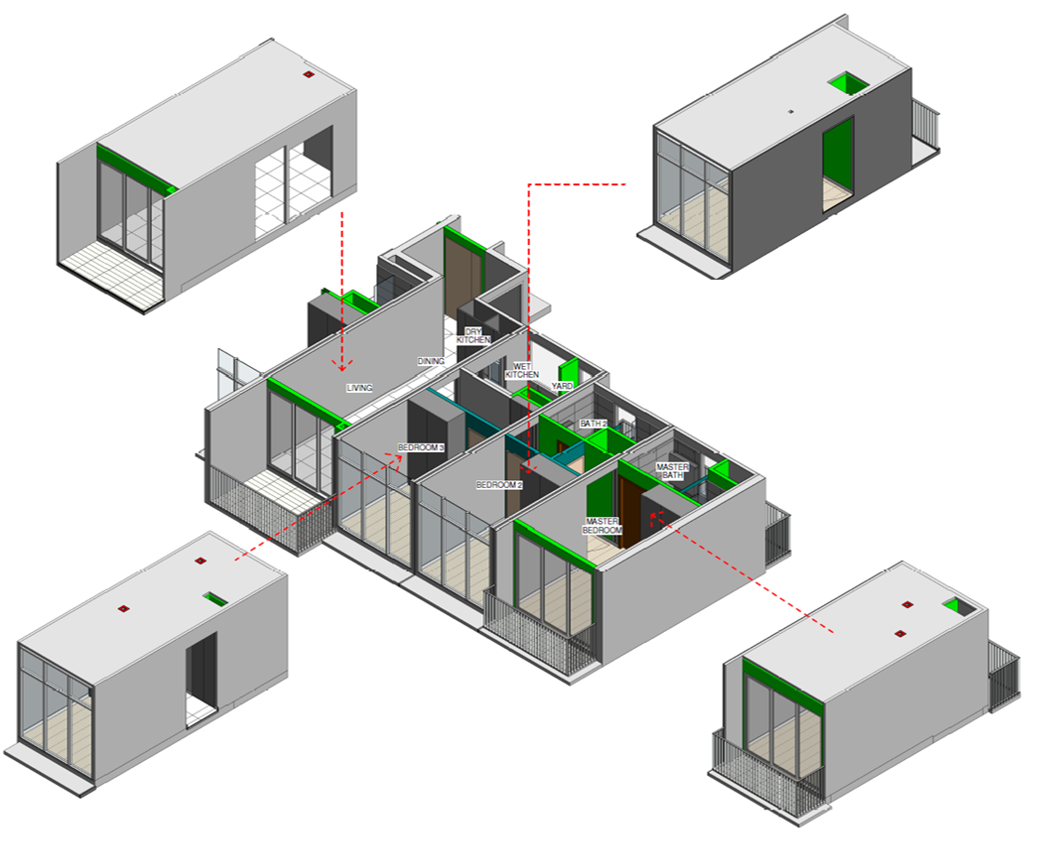

Design for Manufacturing and Assembly (DfMA) is a game-changing method of construction which involves manufacturing off site in a controlled environment, before being assembled on-site. It comprises a continuum of technologies that promote off-site fabrication.

BE professionals would need to draw on various disciplinary expertise and integrate DfMA technologies ranging from prefabricated components to fully integrated assemblies. The DfMA approach leverages on advanced technologies, improving the quality and precision of construction while reducing reliance on manpower.

photo credit: Integrated Precast Solutions

photo credit: TK Modular

photo credit: Greyform

photo credit: Teambuild

photo credit: Woh Hup

photo credit: BBR Construction Systems

Design for

Manufacturing

(off-site and automation)

and Assembly

(on-site)

WHAT ARE THE SKILLS IN DEMAND?

Learn about the skills in demand and desired attributes for these job roles!